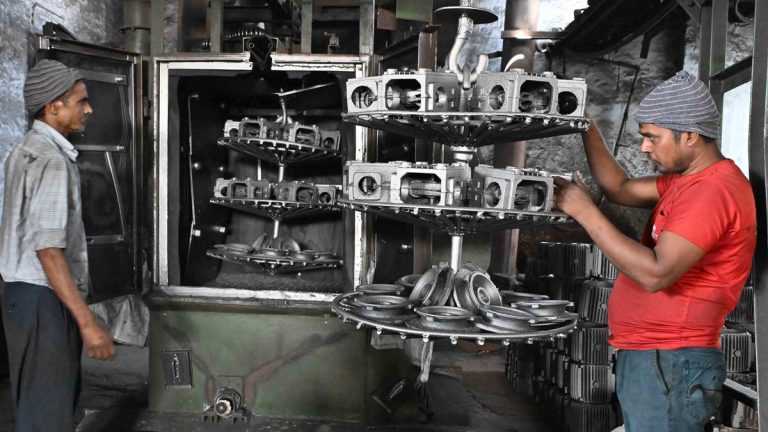

Small-scale foundries in Coimbatore struggle to be cost competitive with the units in the northern States.

| Photo Credit: Siva SaravananS

Rising costs of power, labour and raw materials have dented the competitiveness of the 400-and-odd small-scale foundries in Coimbatore city and nearby areas.

A. Shiva Shanmughakumar, president of the Coimbatore Tiny and Small Foundry Owners’ Association (Cosmafan), said the foundries are operating only 60%-70% of the capacity as they are unable to compete with the foundries in Gujarat, West Bengal, and Uttar Pradesh in costs.

The raw material, including ferrous, coke, and sand, prices are at least 5 % higher in Tamil Nadu compared with the northern States. While the workers are paid over ₹500 a day in Coimbatore, it is about ₹400 in West Bengal for eight-hour shift. Apart from these, the power costs are on the rise in Coimbatore.

“We used to get new orders every day 20 years ago, prompting us to invest and add capacities. There are no new orders since the COVID pandemic and now, we are struggling to retain the existing business,” he says.

President of Coimbatore Tirupur Districts Micro and Cottage Enterprises Association A. Siva Kumar said the foundries in Gujarat are able to supply castings in Coimbatore at prices lower than the cost of manufacturing the castings here. Even larger engineering industries in Coimbatore that have captive foundries have started sourcing their requirements from Gujarat. “Earlier, some foundries used to buy the castings and machine them here. Now, they prefer to buy the machined products from Gujarat mainly because of cost,” he says.

Mr. Shanmughakumar adds that some of the larger industries plan to expand capacities in Gujarat due to the incentives available for investments and low cost of power and raw materials.

“If the automobile sector does not do well, the bigger foundries will start supplying for sectors such as pumpsets that will further affect the small foundries,” he said.

The foundries are looking for support measures from the governments to improve their competitiveness.

Published – February 25, 2025 09:51 pm IST